Understanding the Mice Problem

Signs of a Mouse Infestation

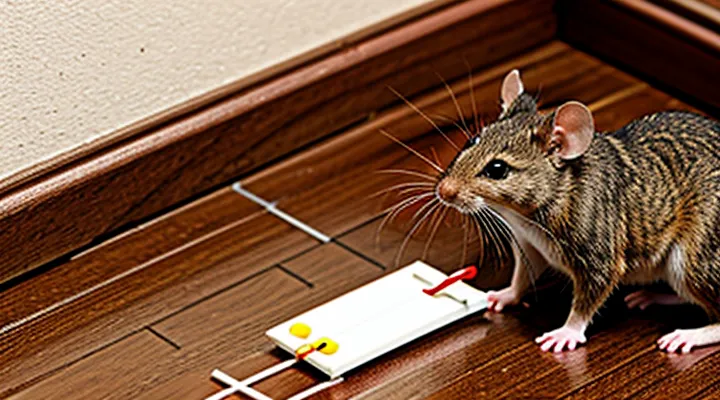

Mouse activity rarely remains invisible. Recognizing early indicators prevents extensive damage and simplifies the construction of an effective trap.

Typical evidence includes:

- Small, dark droppings resembling grain, often found along walls, behind appliances, or near food sources.

- Gnawed edges on wooden furniture, baseboards, plastic containers, and electrical cords; teeth leave clean, crescent‑shaped cuts.

- Scratching or scurrying sounds, especially at night, originating from concealed pathways such as wall voids or attic spaces.

- Accumulated shredded material, including paper, fabric, or insulation, forming nests in hidden corners, behind cabinets, or within ceiling panels.

- Visible tracks in dusty areas, displaying tiny footprints with a distinctive five‑toed pattern.

- Unpleasant, musky odor that intensifies as the population grows, often noticeable near entry points or nesting sites.

- Damaged packaging of stored food, with torn seals and chewed openings, indicating direct access to nourishment.

Each sign warrants immediate inspection. Confirming multiple indicators strengthens the case for deploying a homemade rodent catcher, ensuring timely intervention before the infestation escalates.

Why DIY Traps Are a Good Option

Cost-Effectiveness of DIY Traps

DIY mouse traps offer a clear financial advantage over commercial alternatives. Materials such as wooden boards, steel wire, and simple bait cost a fraction of a store‑bought device, typically ranging from $0.50 to $2 per trap. The initial investment is low, and the reusable nature of the components extends the savings over multiple capture cycles.

A comparison of recurring expenses highlights the disparity. Commercial traps often require replacement after a few uses, adding $5–$10 per unit to the budget. In contrast, a homemade trap can be disassembled, cleaned, and redeployed indefinitely, with only occasional replacement of consumables like bait or small hardware pieces.

Key cost factors include:

- Material acquisition: inexpensive, readily available at hardware stores.

- Labor input: minimal assembly time, often under ten minutes.

- Maintenance: simple cleaning, no specialized parts.

Long‑term cost analysis demonstrates that a DIY solution can reduce expenditure by up to 80 % compared to purchasing multiple commercial traps over the same period. The economic efficiency aligns with the goal of effective rodent control while preserving household finances.

Control Over Trap Design

Effective control over trap design determines capture success. Selecting appropriate materials influences durability and stealth. Thin plywood, sturdy cardboard, or recycled plastic provide a balance between rigidity and concealment. Adjusting dimensions to match typical mouse size—approximately 2–3 inches long—prevents escape while minimizing visual detection.

Key design elements include:

- «Trigger sensitivity» – calibrate the mechanism so a slight nibble releases the latch; spring‑loaded levers or simple snap‑back arms work well.

- «Bait placement» – position attractant at the far end of the tunnel to encourage full entry; peanut butter, dried fruit, or grain are effective.

- «Entry angle» – align the opening at a shallow angle to guide rodents into the interior without hesitation.

- «Escape prevention» – incorporate one‑way doors or inward‑facing flaps that close automatically once the mouse passes.

Customization options such as removable panels allow rapid reconfiguration for different environments. Modular components simplify cleaning and reuse, extending the trap’s operational lifespan. By systematically adjusting these variables, the trap becomes a reliable tool for managing rodent activity in residential or workshop settings.

Essential Materials for DIY Mouse Traps

Common Household Items for Traps

Cardboard and Plastic Bottles

Cardboard provides a lightweight, easily cuttable framework for a mouse trap. Its rigidity can be enhanced by folding edges inward, creating a funnel that directs rodents toward a bait chamber. When constructing the trap, cut a rectangular piece large enough to form a shallow box, then score a narrow opening at one end. Fold the scored line upward to create a hinged lid that snaps shut when a mouse pushes through the opening.

Plastic bottles serve as a durable, waterproof container for the bait and as a trigger mechanism. A 2‑liter bottle, emptied and cleaned, can be sliced longitudinally to produce a lever arm. Attach the lever to the cardboard lid using a small piece of tape or a staple; the lever rests on the bottle’s neck. When a mouse enters the funnel and reaches the bait placed inside the bottle, its weight depresses the lever, causing the lid to close rapidly.

Key construction steps:

- Cut cardboard to form a box with a hinged lid.

- Score and fold the lid to create a spring‑loaded flap.

- Prepare a plastic bottle, remove the base, and cut a length for the trigger.

- Secure the trigger to the lid, positioning it so that mouse weight releases the flap.

- Place attractive bait (e.g., peanut butter) inside the bottle cavity.

- Position the trap along known mouse pathways, ensuring the opening faces the travel direction.

Using these materials yields a low‑cost, reusable trap that combines the structural benefits of cardboard with the mechanical reliability of a plastic bottle. Proper placement and bait selection maximize capture efficiency while allowing easy disposal and reset after each use.

Buckets and Other Containers

Buckets and other sturdy containers provide a reliable base for homemade rodent capture devices. Their weight prevents escape, while the open top allows easy placement of bait and quick inspection of captured animals.

Key considerations for selecting a container:

- Capacity of at least one liter to accommodate a mouse without causing injury.

- Smooth interior surface to discourage climbing.

- Secure lid that can be fastened after capture to contain the rodent safely.

- Material resistant to chewing, such as plastic or metal, to withstand gnawing.

Construction steps:

- Position the bucket against a wall where mouse activity is observed.

- Create a ramp using a piece of cardboard or wood, angled gently toward the opening.

- Place an attractive bait—peanut butter, cheese, or grain—at the far end of the ramp.

- Install a trigger mechanism, such as a balanced stick that releases the lid when the mouse reaches the bait.

- Verify that the lid closes fully and remains locked until manually opened for disposal.

Proper placement near entry points, combined with regular bait refreshment, maximizes capture efficiency while minimizing the need for chemical repellents.

Tools Required for Assembly

A functional homemade mouse trap requires a limited set of reliable tools to ensure precise construction and safe operation.

- Wire cutters – for trimming and shaping the spring mechanism.

- Pliers – for bending wire and securing fasteners.

- Screwdriver (flat‑head or Phillips) – for assembling the housing and tightening screws.

- Drill with small drill bits – for creating entry holes in the trap body.

- Hammer – for gently tapping components into place without damaging delicate parts.

- Utility knife – for cutting insulation or bait chambers to the required dimensions.

- Measuring tape or ruler – for verifying accurate lengths and spacing of trap elements.

Select tools with ergonomic handles to reduce fatigue during repeated use. Verify that all cutting edges are sharp; dull blades compromise the integrity of the trap’s trigger. Keep a clean work area to prevent contamination of bait and to maintain consistent performance.

Safety measures include wearing protective gloves while handling wire and spring components, and securing the work surface to avoid accidental release of tensioned parts. Regular inspection of tools for wear extends the lifespan of the trap and ensures consistent capture efficiency.

Different Types of DIY Mouse Traps

«No-Kill» Humane Traps

Bucket Trap Designs

A bucket trap provides a simple, low‑cost solution for capturing rodents in domestic settings. The design relies on a vertical drop that forces the mouse into a container where escape is impossible.

Materials commonly employed include a sturdy 5‑gallon plastic bucket, a wooden or acrylic platform, a trigger mechanism (such as a spring‑loaded lever or a piece of string), and bait (peanut butter, cheese, or grain). The bucket should be positioned on a stable surface, with the interior lined with a soft material to prevent injury to captured animals.

Construction steps:

- Cut a circular opening in the platform, slightly larger than the mouse’s head, and attach the platform to the rim of the bucket so that it rests just above the opening.

- Install the trigger mechanism beneath the platform, ensuring that a light weight placed on the platform releases it onto the bucket when disturbed.

- Secure bait on the trigger surface to attract the mouse.

- Place the assembled trap along known rodent pathways, preferably near walls or behind appliances.

Design variations enhance effectiveness:

- Inclined‑plane version: replaces the horizontal platform with a sloped board that directs the mouse toward the bucket edge, reducing the chance of premature escape.

- Dual‑bucket system: connects two buckets with a funnel, allowing captured mice to be transferred without handling the trap.

- One‑way door model: incorporates a hinged flap that opens inward when the mouse pushes against it, then closes to retain the animal.

Maintenance involves emptying the bucket promptly, cleaning the interior with mild detergent, and resetting the trigger. Regular inspection of bait placement and trigger sensitivity ensures consistent performance.

Bottle Trap Variations

Bottle traps provide a low‑cost, reusable option for controlling rodent activity. The basic principle relies on a container that guides a mouse toward a narrow opening, where it falls into a holding chamber and cannot escape. Several design variations adapt this principle to different household items and environmental constraints.

A classic soda‑bottle model cuts the top off a 2‑liter plastic bottle, inverts it, and secures it with tape to form a funnel. Bait placed at the base—peanut butter, dried fruit, or a small piece of cheese—draws the mouse forward. Once inside, the mouse cannot navigate the steep walls and slides to the bottom, where a lid can be sealed.

A milk‑jug version uses a 1‑gallon container with a similar inversion technique. The larger volume accommodates multiple rodents before emptying is required. Adding a small ramp of cardboard or wood reduces the angle of ascent, increasing entry success.

Glass‑bottle traps employ a wide‑mouth mason jar fitted with a tapered entry made from a cut plastic bottle. The transparent walls allow visual monitoring without disturbing the trap. A silicone seal prevents escape through the lid.

A bucket trap expands capacity by attaching a funnel made from a cut 2‑liter bottle to the rim of a 5‑gallon bucket. The funnel directs mice into the bucket, where a layer of sand or sawdust provides a comfortable environment for humane release.

A PVC‑pipe variation constructs a 12‑inch length of 2‑inch pipe, capped at one end, with a side opening cut to accept a small bait platform. The pipe’s smooth interior discourages climbing, ensuring the mouse slides to the closed end.

Key considerations for all bottle‑trap designs include:

- Secure attachment of the funnel to prevent dislodgement.

- Placement of bait at the deepest point of the trap.

- Regular inspection and cleaning to maintain effectiveness.

- Use of humane release methods if non‑lethal control is desired.

By selecting the appropriate container, adjusting entry angles, and employing suitable bait, bottle traps can be tailored to various indoor and outdoor settings, offering an efficient, low‑maintenance solution for rodent management.

«Kill» Traps (If Absolutely Necessary)

Snap Trap Modifications

Snap traps offer a reliable base for rodent control, yet simple modifications can increase capture rates and reduce accidental releases.

A reinforced trigger plate, formed from a thin sheet of steel or a stiff piece of cardboard, improves lever strength and prevents premature spring release. Secure the plate with a small screw or zip‑tie, ensuring the spring snaps back with consistent force.

A detachable bait compartment, constructed from a shallow plastic lid or a cut‑out piece of PVC pipe, allows quick bait changes without handling the spring. Attach the compartment with a hinge of spring‑loaded pins, positioning it directly under the trigger edge for optimal scent diffusion.

A calibrated sensitivity adjustment uses a set of stacked washers or a small wooden shim placed between the trigger bar and the base. Each added washer raises the activation threshold, useful when targeting larger rodents or minimizing false triggers caused by vibrations.

A protective escape‑proof sleeve, cut from a length of clear acrylic or rigid acrylic sheet, slides over the trap body and is sealed with a rubber gasket. The sleeve blocks small mammals from slipping out after capture while preserving visibility for inspection.

A reusable spring lock, fashioned from a length of metal rod bent into a hook shape, engages the spring coil when the trap is set. The lock holds the spring in tension, allowing safe transport and storage without risking premature discharge.

Implementing these modifications requires basic tools—drill, screwdriver, and a hacksaw—and common household materials. The result is a more efficient, safer, and adaptable snap trap suitable for various indoor and outdoor environments.

Electrocution Traps (Caution Advised)

Electrocution traps use a high‑voltage, low‑current shock to incapacitate rodents instantly. The device consists of a metal grid powered by a transformer, a trigger mechanism that closes the circuit when a mouse contacts the bait, and a protective housing that prevents accidental contact.

Safety is paramount. Connect the unit to a grounded outlet with a dedicated circuit breaker. Insulate all external surfaces with non‑conductive material. Install the trap out of reach of children and non‑target animals, preferably inside walls, cabinets, or sealed compartments. Verify that the power source complies with local electrical codes before operation.

Assembly steps

- Attach the transformer to the grid according to the manufacturer’s wiring diagram.

- Secure the trigger plate beneath the bait station, ensuring smooth movement.

- Enclose the assembly in a rigid, insulated case with a removable access panel for cleaning.

- Test the circuit with a multimeter; voltage should read within the specified range (typically 2,000–2,500 V).

- Place the bait (e.g., peanut butter) on the trigger plate and position the trap along known rodent pathways.

Regular maintenance extends effectiveness. After each capture, disconnect power, remove the carcass with disposable gloves, and clean the grid with alcohol to prevent corrosion. Inspect wiring for wear and replace the transformer after the manufacturer’s recommended service interval. Proper disposal of dead rodents follows local health regulations.

Building Your DIY Mouse Trap

Step-by-Step Guide for a Bucket Trap

Preparing the Bucket

Preparing the bucket is a critical step in constructing an effective homemade rodent trap. The container must be sturdy, stable, and appropriately sized to contain the target animal without risk of escape.

Key considerations for bucket preparation:

- Select a plastic or metal bucket with a capacity of 5–10 liters; larger volumes increase the chance of injury to the mouse.

- Clean the interior thoroughly using mild detergent and hot water; residual scent may deter activity.

- Dry the bucket completely to prevent slippage of the bait platform.

- Drill a 2‑inch hole near the top edge, centered on the side wall; the opening serves as the entry point.

- Attach a smooth, non‑abrasive ramp leading to the hole; ensure the ramp angle does not exceed 30 degrees.

- Place a small piece of cardboard or plastic sheet at the bottom to facilitate easy removal of the captured mouse.

- Verify that the bucket rests on a flat surface; use a rubber mat to eliminate wobble.

After completing these steps, the bucket is ready for integration with the trigger mechanism and bait placement, forming the foundation of a reliable trapping system.

Creating the Ramp and Trigger Mechanism

The ramp must provide a smooth, downward path that guides a mouse onto the trigger plate without allowing escape. A wooden strip, 30 cm long, 2 cm wide, and 1 cm thick, works well. Secure the strip to the base with two small screws positioned near the front edge, creating a slight incline of 15–20°. Attach a non‑slip pad to the lower surface of the ramp to prevent sliding on smooth floors.

The trigger mechanism relies on a lever that releases a holding bar when the mouse steps on the plate. Construct the lever from a 5 cm piece of dowel, pivoting on a 3 mm stainless‑steel nail inserted through the center of the base. Position the plate directly under the lever’s tip, spaced 0.5 cm apart. When weight is applied, the lever rotates, pulling the holding bar upward and freeing the snap‑back spring.

Key components:

- Ramp: wooden strip, inclined 15–20°, secured with screws.

- Non‑slip pad: rubber or silicone, placed under the ramp.

- Lever: dowel, pivoted on a nail, length 5 cm.

- Trigger plate: thin metal or plastic sheet, positioned under lever tip.

- Holding bar: spring‑loaded steel rod, restrained by lever action.

- Spring: tensioned coil, calibrated to release quickly upon lever movement.

Assembly steps:

- Cut the wooden strip to the specified dimensions and sand edges.

- Attach the strip to the base, ensuring the incline angle is accurate.

- Fix the non‑slip pad to the underside of the ramp.

- Insert the nail through the base, aligning it with the center of the lever.

- Mount the dowel on the nail, allowing free rotation.

- Place the trigger plate beneath the lever tip, maintaining the 0.5 cm gap.

- Connect the holding bar to the spring and position it so the lever’s motion releases it.

- Test the mechanism with a light weight to confirm smooth operation and reliable release.

Proper alignment of the ramp and trigger ensures the mouse moves directly onto the plate, activating the lever without hesitation. Adjust the incline or plate gap if the mouse hesitates, then re‑test until consistent activation occurs. This configuration maximizes capture efficiency while minimizing false triggers.

Assembling a «Flip-and-Fall» Bottle Trap

Cutting and Modifying the Bottle

A plastic bottle serves as the core component of an effective homemade rodent catcher. Proper preparation of the container determines the trap’s reliability and ease of use.

The preparation involves three precise actions:

- «cutting» a clean opening near the bottle’s neck; a sharp utility knife or scissors provide a smooth edge that prevents damage to the animal’s fur.

- «modifying» the cut section to create a funnel shape; trimming excess material yields a gradual narrowing that guides the mouse toward the interior.

- «reinforcing» the funnel with a thin strip of tape or silicone; this secures the structure while maintaining flexibility for the trigger mechanism.

Following these steps produces a sturdy, unobtrusive trap that can be positioned in concealed areas. The resulting funnel directs the rodent inward, where a simple trigger releases the capture mechanism without excessive force.

Bait Placement and Setup

Effective bait placement determines the success of a homemade rodent capture device. Position the attractant where mice naturally travel, such as along walls, behind appliances, and near known droppings. Ensure the lure is concealed yet accessible, preventing premature inspection by the pest.

Select baits that emit strong, lingering odors. Preferred options include «peanut butter», «hard cheese», and small pieces of dried fruit. Apply a thin layer to the trap’s trigger mechanism; excess material may cause the device to snap prematurely or deter the mouse.

- Place the bait directly on the trigger platform, centering it to encourage precise contact.

- Align the trap with established runways, positioning the front edge no more than 2 inches from the wall.

- Secure the bait with a small amount of adhesive tape if necessary, avoiding interference with the release mechanism.

- Test the trap by gently applying pressure to confirm smooth operation before deployment.

Maintain bait freshness by replacing it every 48 hours. Store unused portions in an airtight container to preserve potency. Clean the trap surface with mild soap and water after each capture, then dry thoroughly before re‑baiting. These practices maximize attraction while minimizing false releases, ensuring consistent results in a DIY mouse control system.

Effective Baiting Strategies

Best Baits for Mice

Peanut Butter and Cheese Alternatives

Peanut butter remains a popular attractant for rodent traps because of its strong scent and high fat content, yet several alternatives can match or exceed its effectiveness while addressing dietary restrictions, cost concerns, or local availability.

Common substitutes include:

- Sunflower seed butter – rich in oil, low in allergens, maintains strong aroma.

- Almond paste – dense texture, appealing to mice, suitable for nut‑free environments.

- Cream cheese – soft, moist, releases scent quickly; useful when dairy is acceptable.

- Yogurt‑based spreads – high moisture, mild flavor, easy to apply in small quantities.

- Commercial bait gels – formulated with synthetic attractants, shelf‑stable, minimal mess.

When applying any alternative to a self‑made mouse trap, follow these principles:

- Apply a pea‑sized amount directly to the trigger mechanism to prevent premature release.

- Ensure the bait is fresh; oxidation diminishes scent strength after 24‑48 hours.

- Position bait at the rear of the trap to encourage full entry before activation.

- Store unused bait in airtight containers to preserve potency.

Selecting an appropriate attractant enhances capture rates, reduces trial‑and‑error, and supports a hygienic, efficient trapping system.

Grains and Seeds

Grains and seeds provide a reliable attractant for rodents when constructing a homemade capture device. Their natural scent and nutritional value stimulate foraging behavior, increasing the likelihood of trap engagement.

Effective bait must possess a strong olfactory profile, remain stable under indoor conditions, and be easy to attach to a triggering mechanism. Small, high‑energy kernels meet these criteria, while avoiding moisture‑sensitive varieties that could degrade the trap’s functionality.

« Recommended grains and seeds »

- Sunflower seeds, shelled, unsalted

- Peanut pieces, roasted, unsalted

- Oats, rolled, plain

- Millet, whole grain

- Wheat kernels, raw

Placement of the chosen bait should focus on the trap’s entry point, ensuring the mouse contacts the trigger while attempting to retrieve the food. Secure the kernel with a minimal amount of adhesive to prevent displacement, yet allow easy removal by the rodent. Regularly inspect bait integrity; replace stale or contaminated pieces to maintain optimal attractant potency.

How to Properly Place Bait

Proper bait placement determines whether a homemade mouse trap attracts target rodents or remains ignored. Selecting the right attractant and positioning it correctly maximizes capture rates.

Effective attractants include high‑protein foods such as peanut butter, small pieces of cooked meat, or soft cheese. Choose a scent that remains potent for several hours and avoid dry, crumbly substances that disperse quickly.

Key placement guidelines:

- Position bait at the far end of the trap chamber, directly behind the trigger mechanism, ensuring the mouse must contact the trigger to reach the food.

- Align bait with the natural travel paths of mice, typically along walls or near concealed entry points.

- Secure bait with a small amount of adhesive or a thin wire loop to prevent removal before activation.

- Keep bait size modest; a pea‑sized portion forces the mouse to bite or gnaw, generating the necessary force on the trigger.

After each capture, remove residual scent and replace bait with a fresh portion. Regularly inspect the trap for wear and replenish attractant to maintain effectiveness.

Optimal Trap Placement

Identifying Mouse Hotspots

Identifying areas where mice are most active is essential for placing a homemade rodent trap effectively. Signs such as droppings, gnaw marks, and shredded material indicate recent travel routes. Concentrate on locations where food sources, water, and shelter intersect, because rodents prioritize these zones for foraging and nesting.

Typical mouse hotspots include:

- Kitchen corners near food storage containers

- Behind appliances such as refrigerators and stoves

- Wall voids and baseboard gaps

- Attic insulation piles

- Crawl spaces with easy entry points

Mapping these points on a floor plan helps determine optimal trap locations. Position traps perpendicular to established pathways, ensuring bait is placed toward the far side of the device to encourage entry. Regularly inspect and adjust placement based on observed activity patterns.

Strategic Placement for Maximum Effectiveness

Effective positioning of a homemade rodent catcher hinges on understanding mouse movement patterns and habitat preferences. Mice travel along established routes that hug walls, follow edges of furniture, and converge near food sources. Placing traps directly on these pathways maximizes contact probability.

Key placement principles:

- Align traps parallel to walls, typically 1–2 inches from the baseboard, where rodents seek shelter.

- Position traps behind appliances, beneath cabinets, and inside closets, locations that offer concealed access.

- Install devices near identified food caches, such as pantry shelves, garbage bins, or pet feeding stations.

- Deploy traps at floor level; mice rarely climb higher than 12 inches when seeking shelter.

- Use multiple traps spaced 10–15 feet apart along a single wall to cover the full length of a travel corridor.

Additional tactics improve efficacy:

- Rotate trap locations weekly to prevent habituation; mice may avoid static devices after repeated exposure.

- Combine bait types—grain, peanut butter, or dried fruit—to address individual dietary preferences.

- Monitor trap success daily; replace captured units promptly to maintain continuous pressure on the population.

- Seal entry points after capture to restrict re‑entry; focus on gaps around pipes, vents, and foundation cracks.

By targeting high‑traffic zones, maintaining proximity to food, and employing a systematic distribution strategy, a DIY mouse trap achieves optimal performance and reduces infestation duration.

Maintenance and Safety

Checking and Resetting Traps

Regular inspection of a homemade rodent catcher determines its effectiveness and prevents missed captures. After each night, remove the trap, examine the trigger mechanism, and look for signs of activity such as droppings or gnawed materials. Clean any debris, replace bait if it has lost scent, and ensure the spring or snap component moves freely.

When resetting, follow a consistent sequence:

- Secure the trap on a stable surface.

- Attach fresh bait, positioning it away from the trigger to avoid premature activation.

- Test the trigger by applying gentle pressure; release should cause a swift snap.

- Place the trap along established mouse pathways, aligning the entry point with wall edges or baseboard gaps.

Repeat the inspection‑reset cycle every 12‑24 hours during active periods. Persistent checks identify malfunctioning traps, worn springs, or depleted bait, allowing immediate corrective action and maintaining a high capture rate.

Safe Disposal of Captured Mice

When a mouse is captured by a homemade rodent trap, immediate and sanitary handling prevents disease transmission and secondary infestations. Protective gloves should be worn before any contact, reducing the risk of exposure to pathogens carried by the animal’s saliva, urine, or feces.

The disposal process consists of three essential actions:

- Humane termination – Apply a quick, lethal method such as a carbon dioxide chamber or a commercial rodent euthanasia agent, ensuring rapid loss of consciousness.

- Secure containment – Place the deceased mouse in a sturdy, sealable plastic bag, expel excess air, and tie the knot tightly to prevent leakage.

- Authorized waste removal – Deposit the sealed bag in an outdoor trash container designated for animal carcasses, or follow local municipal guidelines for hazardous biological waste disposal.

After the trap is emptied, clean all components with a detergent solution followed by a disinfectant containing at least 0.1 % bleach. Rinse thoroughly, allow to dry, and reassemble only after the surface is completely dry. This routine eliminates residual scent trails that could attract additional rodents and maintains a hygienic environment for future use.

Hygiene and Sanitation After Trapping

After a mouse capture, immediate sanitation prevents disease spread and deters future infestations. Remove the trap with disposable gloves, place the caught rodent in a sealed bag, and discard it in an outdoor trash container. Clean the trap surface using hot, soapy water; rinse thoroughly, then soak in a solution of one part bleach to nine parts water for at least five minutes. Rinse again and allow the trap to dry completely before storage.

Key sanitation steps:

- Wear disposable gloves throughout handling.

- Seal and dispose of the carcass in a tightly closed bag.

- Wash the trap with hot detergent, rinse, then disinfect with a diluted bleach solution.

- Rinse the disinfectant off, air‑dry the trap in a well‑ventilated area.

- Store the dried trap in a sealed container to avoid contamination.

Inspect the surrounding area for droppings or urine stains. Vacuum or sweep debris, then mop the floor with a disinfectant approved for household use. Replace any food containers or packaging that may have been exposed. Regularly launder cloths or towels used in the cleaning process at high temperatures.

Maintaining a clean environment after each capture reduces the risk of hantavirus, salmonella, and other rodent‑borne pathogens. Consistent application of these procedures ensures long‑term effectiveness of the homemade trapping system.

Preventing Future Infestations

Sealing Entry Points

Sealing entry points prevents rodents from re‑entering the trap area, eliminating the need for repeated bait placement. Identify all potential openings by conducting a systematic inspection of walls, floors, foundations, and utility penetrations. Common entry sizes range from ¼ inch (≈6 mm) to 1 inch (≈25 mm).

• Close gaps around pipes, cables, and vents with steel wool combined with expandable foam; steel wool deters chewing while foam provides airtight sealing.

• Apply caulk or silicone sealant to cracks in drywall, baseboards, and window frames; choose a product compatible with the substrate to ensure long‑term adhesion.

• Install metal flashing or mesh over larger openings such as vent covers or crawl‑space access points; hardware cloth with ¼‑inch openings offers durability against gnawing.

• Replace damaged weatherstripping on doors and windows; ensure a continuous compression seal when closed.

After sealing, verify effectiveness by observing for fresh droppings or gnaw marks over a 48‑hour period. Re‑inspect quarterly, focusing on areas subjected to seasonal temperature changes, which can cause material contraction and new gaps. Regular maintenance of sealed points sustains the overall efficacy of a homemade rodent capture system.

Food Storage Best Practices

Effective rodent control begins with proper food management. Eliminating accessible food sources reduces bait competition and encourages mice to investigate traps.

Secure storage containers must be airtight, constructed of rigid material, and feature tight‑fitting lids. Place containers on elevated surfaces to prevent floor‑level contamination. Regularly inspect seals for wear and replace damaged units promptly.

Maintain a clean pantry environment. Remove crumbs, spills, and packaging debris daily. Use a dedicated cleaning schedule that includes sweeping, vacuuming, and wiping shelves with a mild disinfectant.

Implement the following practices:

- Store dry goods in sealed, rigid containers rather than original packaging.

- Keep bulk items in smaller, resealable units to limit exposure.

- Position food storage away from walls and corners, creating a clear perimeter.

- Rotate stock using a first‑in, first‑out system to prevent spoilage.

- Label containers with purchase dates to monitor freshness.

By limiting food availability, mice are more likely to encounter and enter a homemade rodent trap, increasing capture rates and reducing the need for additional control measures.

Regular Cleaning and Decluttering

Regular cleaning and decluttering create an environment where traps operate with maximum efficiency. Removing food residues eliminates attractants, while clearing clutter reduces hiding spots that allow rodents to evade capture.

Key actions include:

- Sweep floors and vacuum carpets daily to eliminate crumbs.

- Store pantry items in airtight containers; discard expired products.

- Empty trash bins nightly and use lids that seal tightly.

- Organize storage areas, keeping boxes off the floor and away from walls.

- Inspect and seal gaps around pipes, vents, and door frames.

Implement a weekly schedule: dedicate 30 minutes to thorough surface cleaning, another 20 minutes to reorganize storage zones, and a final 10 minutes to inspect trap placement and reset mechanisms. Consistent adherence to this routine sustains bait potency and prevents rodents from establishing new routes.